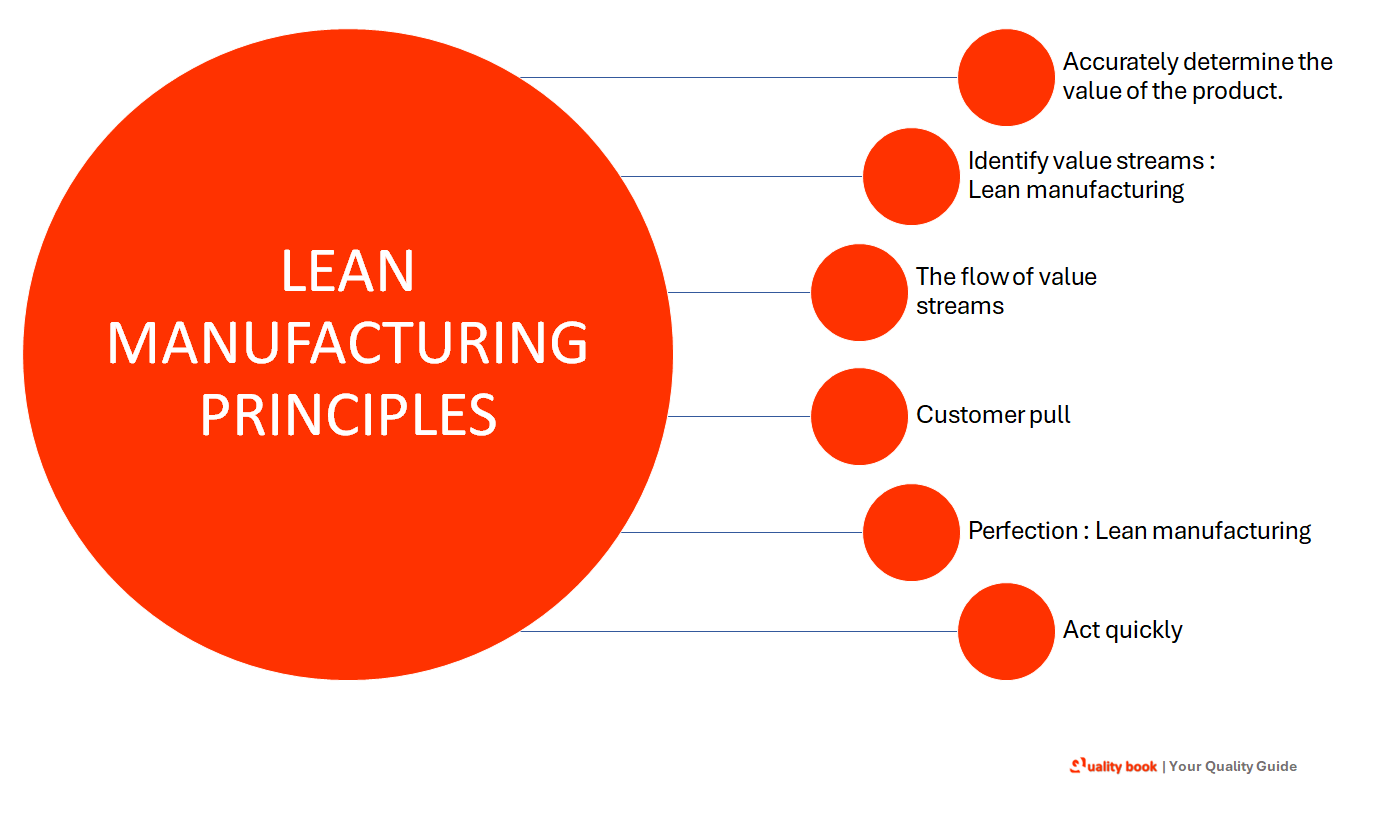

Lean manufacturing | First, accurately determine the value of the product. The key starting point of lean thinking is value. Accurately determining the value of products is an important prerequisite and fundamental guarantee of lean production. At present, in the world, most enterprises have such a misunderstanding…

Accurately determine the value of the product.

The key starting point for lean thinking is value. Accurately determining the value of products is an important prerequisite and fundamental guarantee of lean production. At present, in the world, most enterprises have such a misunderstanding:

- Our customers believe that value is creates by producers, and the labour of producers is the reason for the formation of value. It is also the reason why producers exist;

- In Europe, especially Germany, senior managers of companies are keen to improve the performance and production process of their products (which they believe is the value of the product), and then introduce and market their products to their customers, although the functionality of their products is not practical to users;

- Companies pay more attention to the location of value creation when defining the value of products, and even in Toyota, a pioneer of lean production, in order to meet the needs of the domestic society for long-term employment and stable parts partner relationships, most senior managers also consider how to design and manufacture products in Japan when defining value.

Leaving aside the three most important distortions of value in the world, the definition of value is pervasively distorted by existing organisations, technology, the power of underappreciated assets, and outdated ideas of economies of scale.

Managers around the world love to say,

“We know how to produce this product with the materials and equipment we already buy.”

If the user does not accept, we can adjust the price, or add some decorations.

“In reality, what they really need to consider is fundamentally rethinking value from the user’s point of view.”

Lean thinking therefore starts with a conscious attempt to precisely define the value of a product with a specific function and at a specific price through dialogue with the user.

Identify value streams : Lean manufacturing

A value stream is a specific set of activities that are necessary to make a particular product pass the three key management tasks of any business activity. These three tasks are: the task of solving problems in the whole process from conceptual conception, through detailed design and engineering, to production; Information management tasks throughout the entire process, from receiving orders to making detailed progress to delivery; The task of material transformation from raw materials to final products delivered to users.

Determining the value stream of each product is the second step in lean manufacturing.

In particular, value stream analysis almost always reveals three ways of activity along the value stream:

- There are many clear steps to create value;

- There are many other steps that, although not value-created, are unavoidable under existing technology and production conditions (we call it type one waste);

- There are many steps that do not create value and can be removed immediately (we call this type II waste).

If you examine our production process in this way, you will find that there is so much waste in the production method we are accustomed to, and more importantly: we still do not know about it.

In modern society, where the outsourcing projects of enterprises are gradually increasing and self-made projects are gradually decreasing, what is really needed is for all parties with common interests to voluntarily form a coalition and look at the value streams that have been divided together. This alliance examines beauty as a value-creating step that continues to the end of the product.

The flow of value streams

This is the best stage of lean production: the various steps that are retained and create value flow. Most managers today still believe that activities should be grouped according to types so that they can operate effectively and are manageable.

In the auto industry, Henry Ford and his assistants were the first to recognize the potential of mobility. In 1913, Ford converted final assembly production of cars to continuous flow production, reducing the final assembly workload of Ford’s Model T by 90%. Similarly, Ford applied this principle to other production processes, thereby greatly increasing the productivity of the entire production process. But Ford only found a special case, and the real challenge: creating continuous flow during periods of low-volume production.

The lean approach is to redefine the role of functions, departments and businesses so that they can make a positive contribution to value creation; It is to illustrate the real needs of employees at every point in the value stream, so it is really in the interest of employees to make value flow.

This requires not only building a lean enterprise for each product, but also rethinking traditional businesses, functions, occupations, and the development of lean strategies.

Customer pull

The first visible effect from “department” and “batch” to “production team” and “flow”. Is that the time require from concept to production and sales to delivery. As well raw materials to users is greatly reduce.

After the introduction of flow, products that take years to design can be complete in a few months. Orders that take several days can be complete in a few hours. And lean systems can now make any combination of all the products being produce. So that change needs can be meet in a timely manner.

This approach of lean manufacturing can suddenly result in significant savings from declining inventories and faster payback on investment. It is truly a revolutionary achievement.

Because once you have the ability to design, schedule and manufacture the products that users really need when customers need them, it means that you can put aside sales forecasts and directly produce according to the actual requirements that users tell you. This means that you can let users pull products from you on demand, rather than pushing products they don’t want to users.

Perfection : Lean manufacturing

Miracles begin when organisations begin to precisely determine value, identify the entire value stream, make the steps of creating value for a particular product flow continuously, and allow users to drive value from the enterprise.

It manifests itself in the fact that while delivering a product that is closer to what users really need than ever before, people are endlessly reducing effort, time, space, cost, and error. Suddenly, perfection, the fifth principle of lean thinking, doesn’t seem like a cranky idea.

Why is this the case?

Because the above four principles interact in a virtuous circle. Making value flow faster always exposes the waste hidden in the value stream.

The harder you pull, the more obstacles that stand in the way of value flow will emerge, and you can remove them. Dedicated product teams speak directly to users, always identify value more precisely, and often learn ways to increase flow and pull.

The most important driver for perfection is transparency. Everyone in a lean system, from subcontractors, first-tier suppliers, assembly plants, wholesalers, users to employees, can see everything, making it easy to find better ways to create value. And the improvements employees make get positive feedback almost immediately.

This is a key feature of lean work and a powerful motivator for continuous efforts to improve. When employees begin to get timely feedback from product development, order taking and production flow, and can see customer satisfaction, most of the “carrot and stick” approach in traditional management is unnecessary.

Act quickly

When we have the concept of Lean, the transformation to lean becomes the most important goal in front of us, and it is also the most difficult step.

Start by overcoming the inertia that exists in gray-domain organizations. In order to quickly produce results that your organization cannot underestimate. You need a change agent. And need to master the essence of lean knowledge (which can also be master by multiple people). Use some type of crisis as a lever for change, draw a value stream map, and be determine to quickly and radically improve your value-creating activities.