What is process capability?

Process Capability Measure of how capable the process is to meet customer requirements; compares process limits to tolerance limits.

It can be appearances at short term and long term performance of a process with regard to customer satisfactions. It is looks long term performance level of the progression after it had been conveyed under statistical control. In short, process capability is the range over which the natural variation of the process occurs as determining by the method of natural variation. It is also the capable of the arrangement of manpower, machine, method, material and measurements.

Intro :

To produce a product that will constantly meet the customer probability and design requirement.

The purpose of process capability to carryout process potential / capability studies. To determine whether the process, given its natural variation, is capable of meeting establish customer specification and expectations.

It is measures how well manufacturing processes are currently performing with respect to the product specifications. It indicates process capability is characteristic reproducibility of process’ outcomes.

The capability is often consider as the part of the production. Which will be within the product specification tolerance. It can be measured in the frequency of the defect produced in:

Percentage (%)- Parts per million (ppm)- Parts per billion (ppb)

What is process capability study?

Process capability study is a systematic procedure that uses graphic techniques. To detect and reduce the unnatural causes of variation until an accurate of statistical control is reached. Once study is completes, you will identify the natural variability of the process.

The study provides a model to realize how the process is operating relative to the specification. Process capability study provide metrics for quantifying that variability through display at how variability is affecting the processes. And study also provide data concerning what the process could do under best circumstances, and thus gives a performance target to eliminate.

What process capability study can:

- Specify the consistency of the process outputs.

- Show the degree to which the output meet specifications

- Be use for evaluation with another process or competitor.

Why should I know the capability of processes?

- The study provide a standard point for existing manufacturing process to understand how the process is functioning relative to the specifications.

- Process capability measurements allow analyst to summarize process capability in terms of key metrics and percentages.

- Study provides which manufacturing processes are performing well under specific conditions.

- You can predict the levels to which process able to maintain tolerances, as on the rule of possibility, and also able to calculate how frequently the process will meet the specification / customer requirements.

- You can easily know the capability of your processes, and easier for you to specify which process is better the quality performance requirements for new equipment, machinery, parts and processes.

- To review the processes under statistical control, you can identify fundamental changes through even redesigning alternative / or new process that eliminates the sources of variability.

Process variation

Process variation is the unavoidable differences among specific measurements or things produced by processes. Sources of variation can be in different – different forms like:

- (1) Unit – positional variation.

- (2) Unit to Unit variation.

- (3) Production lines to Production line variations.

- (4) Time – time Variation.

- (5) Measurement errors like repeatability & reproducibility etc.

There are two type of variation – In the processes, natural variation due to the cumulative effect of many minor unavoidable causes and a process operating with only chance cause of variation present is said to be in statistical control.

The variations occurred due to may improperly adjustment of machine. Defective raw materials or machine / equipment operator error, variation are occurred which is calls assignable cause of variation.

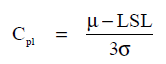

See example, Process variation in Processes:

Process relation with Specifications

- If the process Variation is little relative to the product specifications. So that the process mean can shift about without initiating the process to reduce its capability. This will reduce the defects per millions, reduce the cost of quality and hence increase profitability.

- If the process variation is large relative to the specifications. Such that the process must remain well position for the capability to be maintain at an acceptance level.

- If the process variation is large relative to the specification. So that the process cannot be consider capable regardless of the process centering. Its serious issues need to reduce immediate.

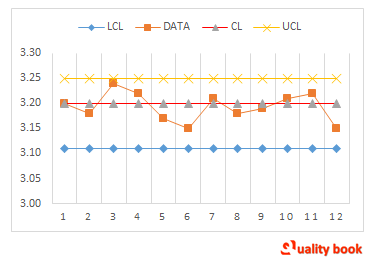

Process Capability Index

Cp & Cpk are statistical process indexes, these indexes display if the process is capable of producing features within the acceptable tolerances. The indexes i.e. Statistical process control (SPC) is the tools of statistical methods or techniques such as control chart to explore a process results and to take appropriate actions to attain and sustain a state of statistical control and to improve the process capability. To manage capability index needs measures of process capability.

There are four most common and timed tested measures are:

| INDEX | USAGE | EQUATION |

|---|---|---|

| Cp | The Cp index assesses whether the natural tolerance (6 σ). Capability for two-sided specification limit, irrespective of process center. | C = UCL – LCL / 6 σ or C = Engineering Tolerance/Natural Tolerance |

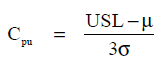

| Cpu | Process Capability relative to upper specification limit. | (USL – X-Bar) / 3 σ

|

| Cpl | Process Capability relative to lower specification limit. | (X-Bar – LSL) / 3 σ

|

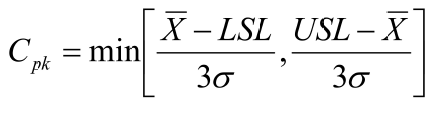

| Cpk | Process Capability for two – sides specification limit accounting for process centering. |  |

General Process capability procedure

- The manufacturing / production supervisor / manager shall prepare a capability study plan clearly indicating the product, characteristics, specification, number of unit and the frequency of study.

- Based on the planning, the further study carryout to collect the requires number of unit at various time intervals on particular day. Measure and record the dimensions in the study report. Calculate the mean (X Bar) and standard deviation (Sigma – Sample) for the reading.

- Calculate Cp Index which is the ratio of the specification allowable to the width of the distribution of the process characteristic (Six standard deviation)

Cp = Specification allowable / process with:

= (USL – LSL ) / ( 6 x Sigma)

Where ULS – Upper Specification limit & LSL – Lower Specification limit - Calculate CpK index as below:>> For a one-sided specification, CpK is the ratio of the distance from the process average, divided by three standard deviations (The process half-width)

CpK = (X bar – LSL ) / (3 x Sigma ) or (USL – X bar ) / ( 3 x Sigma )

>> For a two-sided specification, CpK is the ratio of the distance from the nearest specification limit to the process average, divided by three standard deviations.

CpK = Min of { [USL – X bar) / (3 x Sigma) ] or [X bar – LSL ) / (3 x sigma) ]}

Interpretation of Cp and CpK index values:

| INTERPRETATION OF CP AND CPK INDEX VALUES | CONDITION |

|---|---|

| Cp < 1 | then the process variation exceeds specification (Defectives are being made) |

| Cp = 1 | then the process is just meeting specification (A minimum of 0.299% defectives will be made, more if process is not centered) |

| Cp > 1 | Then the process variation is less than specification, however, defectives might be made if the process is not centered on the target value |

| CpK < 1.33 | then the process is not capable |

| CpK = 1.33 to 1.67 | then the process is marginally capable |

| CpK > 3 | then the process capability is excellent; it is highly capable |

| If Cp & CpK are High | then process is stable and in control (Maintain the centrality) |

| If Cp is High & CpK is low | then the process is potentially capable but the process performance is not adequate (Aim for centrality of the process with reference to the specification mean) |

| If Cp & CpK are low | Them improvements needed to make the process potentially capable (Reduce process variability or seek alternate process, machine etc.) |

- The production manager / supervisor shall also identify critical components and the process potential / capability study shall be carried out in the same way as mentioned with + / – 4 Sigma variation.

- The production manager shall plan to develop and improve the processes up to +/- 6 Sigma.

Conclusion:

A study is the end results of the analysis done on process outcomes results. The study reflects what our customer sees, and its indicates what our short terms and long terms situation. Generally, process capability is accompanied when the prior to taking delivery of new process equipment.

Before approving newly installed process machinery and equipment for real production use, as production begins, to establish capability of equipment, tooling, material, operator combination. For the study, needs to train engineers and supervisor measurements, study guidelines, variability of the processes so that the performance potential can be detected under normal in control condition.