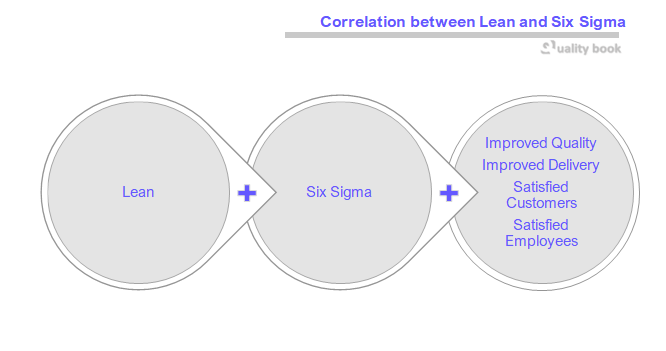

Lean operates on the principles of removing wastes of any process, thus accelerating the velocity, and reducing process costs. It basically focuses on speed. Six Sigma operates on the principles of reduction of variations and improvement of process yield.

It basically focuses on the quality of any given service or product. Quality and speed and complementing factors, and thus Lean and Six Sigma methodologies complement each other.

To have a competitive edge over others, you should effectively combine both Lean and Six Sigma tools and principles. Their Correlation holds the perfect toolkit for addressing almost all types of process problems.

Lean Six Sigma

Six Sigma contains certain drawbacks which can be rectified by Lean. For example, Six Sigma effectively eliminates defects, but it does not address the issue of process flow optimization, which is done by Lean.

Lean Six Sigma helps to create an effective process stream map and helps identify value add costs and non-value add costs. It helps to address CTQ (customer Critical to Quality) by capturing the voices of customers and using simulation methods. Based on their delay time, the projects within a process are prioritized.

This helps to identify activities involving high defect rates (Six Sigma tools) or long setups (Lean tools). The manufacturing process highly benefits from a reduction in capital expenditure and working capital.

Lean provides tools for reducing lead time (like setup reduction) and for controlling lead time (like Pull systems). Lean also fits very well within the DMAIC process of Six Sigma and has proved to be an important complement to Six Sigma.

The Kaizen approach in Lean is also used for accelerating the rate of improvement.

Many organizations have benefitted dramatically from the combined use of Lean and Six Sigma methodologies. Lean Six Sigma methodology has been applied in all kinds of processes ranging from manufacturing to healthcare in the last 15 years.

Why we do correlation Lean and Six Sigma?

The correlation of the lean and six sigma will becoming a more powerful approach for process improvement. Because the lean concept focuses on the elimination of waste, while six sigma helps to reduce variation in the process.

When these both methodologies can jointly address aspects of process improvement with different angles of views. Hence, the manufacturing processes will become more productive and efficient.

As we discuss, the lean encourages the elimination of wastes, and six sigma encourage for reducing defects and minimizing process variability, as results the manufacturing unit can enable to focus on the continuous improvement.

Individual benefits of lean and six sigma?

Here is a table that describes individual role of Lean and Six Sigma for the implementation of processes:

| LEAN | SIX SIGMA |

|---|---|

| Focus on waste | Focus on reducing variation |

| Streamline processes | Improve process quality |

| Eliminate non-value add | Reduce defects |

| Optimize resources | Minimize process variability |

| Kanban, 5S, VSM, Kaizen | SPC, DOE, Root Cause Analysis |

As you can see above table, there is individual features are mentioned. Think about it, if both approaches will be works combined, and target same issues or process. Then there is scope of the improvement will be double. You can expect significant and sustainable improvement from this Correlation.

However, it all depends on the organization, how they deploy both the tools, what is application and how they implement it for their processes.

How does the correlation of lean and six sigma work?

The correlation of these both methodologies are usually working together in many manufacturing units. It is works fine, and tune very well each other, when you practically work on it.

It is actually up to you, how you strictly follow these both methodologies principles, tools, and its excellent use at manufacturing floor.

Because of its common goals and principles, the correlation is effectively works and give us better results when it is correlated.

Here are some ways that the correlation of lean and six sigma works:

| SHARING GOALS |

|---|

| When we work on the correlation of lean and six sigma methodologies it will be definitely improve efficiency, quality, and customer satisfaction. These both are sharing goals to focus on the same targets such as reducing waste, defects, and variability in the manufacturing processes. Even they are also fucus on identifying and eliminating non-value-added activities and processes. |

| OVERALL IMPROVEMENTS |

| It is much important that for usually in the manufacturing units, the continual improvement should be on top of the priority. We should promote the continuous improvement as culture. This mean, departments of manufacturing unit should always strive to make their processes better. |

| CORRELATION WILL WORK BETTER THAN INDIVIDUAL – I BELIEVE. |

| As you well know lean is focus on identify waste and inefficiencies in the manufacturing. And Six sigma is focus on reduction of defects, and variability in the process. When these methodologies works together or Correlation, it may target same process with all their features. This will be look like a filtering entire process by lean and six sigma methodologies. |

| TUNE BETTER OF TOOLS & TECHNIQUES. |

As you know, Lean & Six sigma using wide range of tools & techniques to reach their aims. Such as:

|

| The Correlation of these both methodologies will be tune better for practical works at floor level. It can be used together to achieve greater results. |

| If your manufacturing processes having a serious issue such as overproduction, unaccepted waste generation from the production, lead time, transportation issues in processes, or even time wastes etc. You have to definitely review this article and try to implement these both methodologies, with advice of Experts. |

What is the benefit from correlation Lean and Six Sigma?

The lean and six sigma both are powerful tools, the correlation between lean and six sigma can enhance the benefit to the company. Here as below, i tried to describe the details of the benefits that you can get from this Correlation:

Comprehensive approach.

By the way, lean and six sigma are two complementary methodologies. But still these correlations have been widely adopted in the manufacturing as well as service sectors. Because it is directly targeted on the reduction of waste, increase efficiency, improvement of quality etc.

A comprehensive approach of these both tools can significantly be helpful to improve the overall operational performance. Here we have to note down the points: Lean focuses on waste reduction, process improvement, while six sigma is actually data-driven approach for problem-solving and quality improvement tool.

Combining these two methodologies may much appreciate helpful to improvements.

Improve the quality.

When we talk about the improvement in quality, we have to focus on some basic tools that are powerful to help you to understand areas where possibility of improvement. Here are points that describe what you can get using this correlation:

- Identify and eliminate waste in manufacturing processes.

- Reducing variation and defects of product and processes.

- Focus on customer needs.

- Encourage involvement of employees in process improvement.

- Identify areas for improvement & continuously monitor and improve processes.

Using these two approaches, you can get better results at every level of the processes.

Cost savings.

This is basic thing that when you eliminate waste, and optimize resources for your manufacturing processes, overall costs will definitely be reduced significantly. This correlation makes your processes more optimized and efficient.

Increasing efficiency.

First of all, you have to understand – what things are making your processes inefficient? – No doubt it is waste, process variations, slow cycle times etc. Without any surprise I would like to tell you, lean & six sigma target the same things that making your process inefficient. If you implement these approaches, the process efficiency will definitely increase.

Gaining competitive advantages.

Using this correlation of lean & six sigma, I am damn sure! that your business can gain a competitive advantage in your market segment. Make your time more productive using these approaches. It can improve product quality, cost effective, increase efficiency, reduce lead time, etc., what more do you need?