Increasing the value of the enterprise while simultaneously honouring the social responsibility of the enterprise. : Successful executives are highly focused on one fundamental goal

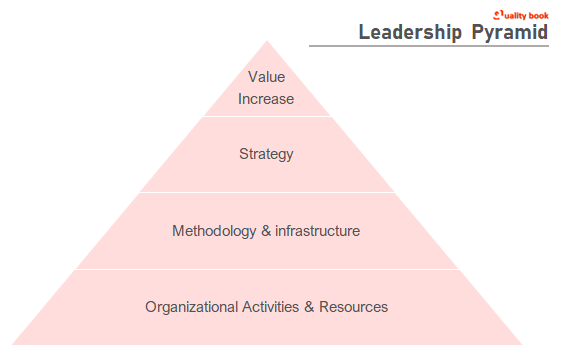

Increasing the value of the enterprise typically involves three steps shown in below image. First, executives determine a strategy that will increase the value of the enterprise. Secondly, they identify a methodology, or infrastructure to best support the strategy. Lastly, the methodology or infrastructure aligns the organizational activities and resources by using the methodology to support the strategy.

To this end a number of strategies can be employed. The common strategies address profitable revenue growth and lowering business cost structure. Examples of strategies address decreasing operating costs, increasing key customer retention, increasing customer value through product enhancement, reducing cycle time of manufacturing or service delivery, leveraging economies of scale, etc.

Methodologies

The methodologies to accomplish these goals have been plentiful in the past 30 years. Most recently, we have seen a wave of industry consolidation primarily through mergers & acquisitions to capture the benefits of economies of scale. Financial engineering has reached new levels of sophistication, and the arrival of financial derivatives has brought new opportunities to many organizations and their trading partners. Prior to that, Re-Engineering was used extensively to capture the opportunities with regard to organizational structure and agency costs. Total Quality (TQ) and Cost of Quality (COQ) were implemented throughout the 80ies to address quality related issues. In the end all methodologies focus on increasing enterprise value.

In the past ten years a fundamental methodology has emerged and rewarded business leaders with measurable results to the bottom line while simultaneously improving organizational culture. The methodology, Six Sigma, improves the processes that constitute the business engine. The approach has been so successful that companies like Motorola, AlliedSignal and General Electric have used it to substantially improve stockholder value.

It has been recognized at Wall Street as a sound business initiative. Six Sigma eliminates cost and increases value like few other process improvement methodologies have. In part because it forces quantitative measurements on the results of organizational activities. It has been utilized in manufacturing as well as in service and other non-manufacturing environments. It is successful because non-value-added expenses often represent up to 50% of an organizations cost structure. Thus providing savvy leadership a veritable goldmine of quantifiable opportunity.

Tools

If the prospect of saving money alone is not convincing enough, this effort is accomplished largely with internal, ergo existing resources combined with the support of only a few external experts.

At the technical core, Six Sigma provides statistical tools to the broader organization. Associates at various levels are deployed on key projects to improve operational performance rapidly. The methods are used to gain fundamental process knowledge such that variation related issues are eliminated. Typical opportunities that are addressed with this approach are: Low yield, warranty claims, defects, excessive inspection, high inventory levels, administrative and financial errors, etc.

In assessing Six Sigma, one must realize that it is not just the use of statistics, but rather the element of critical data acquisition in conjunction with the tools that enables the capture of previously unattainable opportunities.

The types of tools taught in a Six Sigma program vary depending on the industry and business issues at hand. Common examples of tools used are process mapping, failure modes and effects analysis (FMEA), Measurement System Evaluation (MSE) design of experiments (DOE), components of variation (COV), techniques for experimenting in noisy environments, and statistical process control (SPC) for process investigation. In addition, thought process mapping (TPM) is taught as a tool to support critical thinking and communication.

Mapping

Thought Process Mapping ensures that all projects are worked on a path of efficient and effective solution generation. All of these tools are then integrated into one cohesive methodology providing the organization with the know how to capture opportunities and the ability to communicate more clearly.

Just as important as the technical component of Six Sigma is the organizational infrastructure of the approach. The program lays a framework for process improvement that the entire organization, regardless of function, can utilize to identify and capture improvement opportunities. The framework, as much as the actual tools, may explain why Six Sigma has been so successful.

The Six Sigma infrastructure consists of the following elements:

- Project Identification Process

- Leadership Training

- Practitioner Training

- Project Tracking and Support

A key element to Six Sigma is the fact that it is implemented as a cornerstone to the business strategy. Business results are delivered by individual contributors and teams tasked to complete business critical projects. As such it is imperative that the projects worked are identified in coordination with the business goals.

This linkage makes Six Sigma the operations improvement mechanism enabling an executive strategy. Only those projects that are on the leadership agenda are addressed as part of the Six Sigma program. This process ensures managerial motivation to adequately support the project work. It ensures key business goals set by executives are accomplished by focusing activity and resources on those projects that link to the goals. It drives organizational focus to strategy related activity.

Business Thinking

By using the infrastructure, associates work on projects that have quantifiable results, introducing the entire organization to “business thinking”. While some organizations have driven business thinking into the lower ranks, many have not. Getting the entire organization to think and behave with a business mindset, value generation being job number one, versus a functional mindset, like engineering, marketing or accounting, generates the culture required in a fast paced, global marketplace.

The leadership training portion of the infrastructure is designed such that leadership gains not so much an in-depth knowledge of statistical methods but the knowledge how to best utilize individuals equipped with these methods. Its focus is on project selection, project tracking and required behavior changes to best support fast paced project teams. The leadership training will also, one more time, reinforce the executive agenda.

Training

The Practitioner Training is designed to equip the organization with the tools and a project management framework to rapidly and successfully complete projects. Depending on the ability, time commitment, and project opportunities, three training levels are commonly found:

- Greenbelts

- Blackbelts

- Masters

Greenbelts are formally trained for the duration of 5-10 days. They are exposed to the fundamental tools that are required on almost any project. Greenbelts are typically not removed from their day-to-day function and complete project work as part of their normal task.

Blackbelts are usually trained for 20-25 days over the course of 4-5 months. They typically attend 5 consecutive days of classroom training, then apply the learned principles on their respective projects before they return to the classroom for the next 5-day session of training. Blackbelts are typically dedicated to the improvement effort for the duration of the training.

Master’s are those individuals that may eventually replace the external consultants. They should be rigorously trained and gain additional, technically much more complex, project experience. The duration for master’s training is 12-18 months.

Another key element of the Six Sigma infrastructure is project tracking and support. Project tracking should be well integrated into the business tracking mechanism. Management must have visibility of project progress, such that poor performance is immediately recognized and addressed.

Supports

Project support is most often the determinant of truly successful programs. Especially when the organization is new to the methodology, the availability of both on-site and off-site support is critical to ensure projects move quickly. Many of the tools require some application experience and until training participants have gained initial experience, they should be provided with personal mentors to ensure quick help.

The infrastructure associated with Six Sigma is applicable across industries, functions, and cultures. The detailed program content, the exact tools and their presentation must be altered and supplemented to provide the most efficient tool set given the operational challenges and opportunities of the specific Enterprise Value.

Programs

Many traditional programs are rooted in discrete parts manufacturing. For processes such as refining, or any form of chemical processing, additional techniques are required to complement the program to account for the technical differences in continuous processes. In service applications, yet other tools must be provided in addition to the ones traditionally used in manufacturing. Some industries are still underserved in regard to Six Sigma, primarily those outside of discrete parts manufacturing. However, programs tailored to those industries are now available in the open market.

Six Sigma has proven to be a substantial value generator for many organizations. Given an achievable ROI of 700%, the decision to press forward with this approach has not been difficult for many executives. Some executives that have not implemented this approach may find themselves missing a substantial opportunity for low-cost value generation. If operational opportunities exist, Six Sigma has proven to be a methodology executives can utilize to increase enterprise value without making large investments.