Lean Six Sigma concept is an integrated concept, uniting the most popular in the 90s of the past Century of Quality Management Concept: The Concept Lean manufacturing, focused on the elimination of losses and unproductive costs, and the concept of “Six Sigma”, aimed at reducing the variability of processes and stabilization of product performance.

First experience Lean Six Sigma was described in 2001, And by 2003, a number of books with detailed descriptions were theory published, practice, and benefits of using Lean Six Sigma. The Lean Six Sigma concept incorporates the best, which allows businesses to achieve the largest economic results in the shortest possible time. The Lean Six Sigma concept has a wide range of applications and can be used by any enterprise, regardless of size and field of activity.

What is the Lean Six Sigma concept?

Does its use always bring economic benefits? How applicable is the Lean Six Sigma concept? to the conditions of functioning of enterprises?

The period of formation of the concepts of “Six Sigma” and “Lean Manufacturing” fell in the mid-80s of the last century. At that time, the highest requirements for product quality and resource saving were set in the production industry.

The concept of “Lean Manufacturing” was created as a methodology for optimizing costs in the automotive industry. The Six Sigma concept owes its birth to a program to combat defects in finished products by reducing process variability in semiconductor manufacturing. It is quite natural that the pioneers in the application of these concepts were manufacturing enterprises.

[1]

The stages of development of the concepts of “Six Sigma” and “Lean Manufacturing” repeat the stages of development of standards for quality management systems (QMS). The progenitors of the most used standards for the ISO 9000 series QMS were standards containing quality assurance requirements for the military industry, and later for the automotive and mechanical engineering industries.

[2].

The beginning of the 90s of the last centuries can be described as a time of active use of standards for management systems and the concepts of “Six Sigma” and “Lean Manufacturing” in non-traditional areas for them. Ever-increasing competition pushed manufacturers of services and intellectual products, state, and public organizations to search for new ways to maintain and increase demand. From the point of view of consultants, the prospects for adapting quality management standards and concepts to the needs of enterprises in these areas were extremely broad. For example, 80% of the gross national product of the United States is currently produced in the service sector.

Having been repeatedly tested at enterprises in both the production and non-production spheres, the concepts of “Six Sigma” and “Lean Manufacturing” have gained versatility. As a result, the name “Lean manufacturing” – “Lean manufacturing” – was transformed into “Lean” – “Lean Management”. By the mid-90s, the concepts of “Six Sigma” and “Lean Management” became one of the most popular areas of the consulting business in quality management.

[3].

Why did this happen?

The ratio of the “number of successful implementations” to the “total number of implementations” is higher compared to other methods and concepts of quality management.

[4].

In addition to the subjective success factors due to the efforts of training centers and consulting firms, there are a number of objective factors. With regard to the Six Sigma concept, among the success factors, we highlight the most significant – high organization. Here it is appropriate to recall the meeting with American colleagues at the conference “Customer Satisfaction and Business Improvement” of the American Society for Quality in November 2003.

The result of these discussions can be formulated as follows: “the main reason for the success of American companies is high organization, and failures are excessive over organization.” High organization is one of the most distinctive features of American business, which is expressed in the following:

- All activities are carried out within the framework of projects, each of which has set goals, timing, budget, allocation of responsibilities and powers, requirements for determining risks, record keeping, etc…

- The requirements for the knowledge and skills of the personnel involved in the projects are clearly defined and classified into categories (“black belt”, “green belt”, etc.).

- The progress of each project is regularly monitoring from with the help of an established system of measurable indicators – “metrics”.

There are several other factors for the success of the Six Sigma concept. The procedure for its implementation is formulated in the Handbook of the American Quality Engineer

[5]

As “definition, selection and execution of projects.” At the same time, the greatest attention is paid to the choice of projects, which should be justified both from the point of view of the greatest economic feasibility and from the point of view of the possibility of implementation in practice. It is interesting to note that a specialist who has a “black belt”, despite the hired nature of his work, has all the advantages of an external consultant, namely:

- it is independent and can make impartial assessments and judgements.

- He is not perceived by his colleagues as “one of the us”, his opinion is listened to as the opinion of an expert in matters of quality improvement.

- The reputation and future career of a black belt specialist is fully determined by the success of the projects he implements within the framework of the Six Sigma concept, which explains his high level of motivation.

Specialists with a “black belt” can be hired on a part-time or full-time basis. To assess the results of their activities, “lower and upper tolerance limits” are established – for a year of work, a specialist of this category, hired for a full working week, should bring savings to the enterprise from 500 thousand to 1 million dollars.

[6].

Going beyond the lower limit of tolerance means a mismatch of qualifications, exceeding the upper limit is unlikely. The concept of “Lean Management”, which was first formed in Japanese enterprises, has other success factors. High organization is no longer a factor in achieving success, but a result. The achieved high organization of processes (both main and auxiliary) allows the company to save a significant number of resources.

In addition to the fact that the concept of “Lean Management” implies fundamentally new approaches to the culture of management and organization of the enterprise

It also offers a set of tools that allow you to reduce the cost and speed up processes. The main tools are already well known to quality specialists: just in time, 5S, kaizen (the concept of continuous improvement), value stream management, poka-yoke (error protection method), etc. In this list, practitioners highlight “value stream management” as one of the most effective tools in achieving the goals of the “Lean Management” concept.

[7].

Basics of integration.

So, what does the concept of “Six Sigma”, which has American roots, have in common with the concept of “Lean Management” born in Japan? First of all, there is a mutual interest in a single process. This is what significantly distinguishes them from many “venerable predecessors” focused on universal coverage and makes them similar to the concepts of the new generation, such as “business process re-engineering.”

[8].

The concepts of Six Sigma and Lean Management complement each other perfectly. Answers to questions regarding the complementary of these concepts can be found in the publications of Michael George, one of the first ideologists of Lean Six Sigma.

What gaps in Lean Management can Six Sigma fill?

- The concept of “Lean Management” does not establish requirements for the form of implementation of the concept and the infrastructure required for this. Therefore, the success of “Lean Management” largely depends on the initiative and organizational skills of managers, but with a change of managers, everything can collapse. The concept of “Lean Management” lacks formalized commitment from senior management, formalized training, planned allocation of resources, tracking success with the adoption of corrective actions, etc. This is exactly what every Six Sigma textbook says.

- The concept of “Lean Management” is not sufficiently focused on the needs of consumers. Their Satisfaction is not directly related to its main goal – the elimination of losses and unproductive costs. In the concept of “Six Sigma” focus on consumers is a key element. This is confirmed by the fact that all the main metrics of this concept are based on tracking the relationship of process parameters and product characteristics with the specifications set by consumers. The key principle of the Six Sigma concept of DMAIC begins with the definition of customer requirements: Define – define, Measure – measure, Analyze — analyze, Improve — improve, Control — Manage.

- There are defects in the concept of “Lean Management” and inconsistencies are recognized as one of the main sources of losses in the enterprise. At the same time, it Methods of statistical process control to eliminate losses are not considered. Concept “Lean management” is not focused on search sources of process variability and ways to reduce variability, which is one of the main ones elements of the Six Sigma concept.

What gaps in Six Sigma can Lean Management fill?

- Defects are the main target of the concept of “Six Sigma” are only one of many types of losses in enterprises. In the classical theory of the concept of “Lean Management”, seven types of losses are distinguished: overproduction, waiting, transportation, non-value-adding activities, availability of stocks, movement of people, production of defects. Many authors distinguish additional types of losses. For example, “false economy”, consisting in the use of cheap and low-quality raw materials. “Diversity” as a result of the use of non-unified elements in processes.

- Six Sigma does not draw parallels between quality and customer satisfaction, on the one hand, and duration and the speed of execution of processes, on the other. At the same time The time duration of the process is directly related with customer satisfaction in the provision of services, and for production processes – with frozen funds in the form of stocks that are in the mode waiting. In the concept of “Lean Management” Analysis of time as one of the main resources process is a key focus.

- The Six Sigma toolset limits the possible coolness tasks to be solve. Process improvement within the framework of the Six Sigma methodology is carried out mainly by reducing the variability of processes by statistical methods and redesigning processes using the DFSS (Design for Six Sigma) method. The Six Sigma methodology misses such opportunities for process improvement as reducing unproductive activities, reducing waiting times, reducing inventories and transportation costs, optimizing jobs, etc.

Happened as a result of the integration?

Filling the “gaps” described above within the framework of the integrated concept of Lean Six Sigma is given in Table. 1.

| The main elements of the concept | Six Sigma Concept | The concept of “Lean Management” | Lean Six Sigma Integrated Concept |

| Formalized management commitments | √ | √ | |

| Formalized allocation of resources | √ | √ | |

| Formalized training and distribution responsibility and authority | √ | √ | |

| Gradation of specialists involved in projects (Black Belt category, etc.) | √ | √ | |

| Implementation of the concept in the form of “determination, selection and Execution of projects” | √ | √ | |

| Short-Term Improvement Projects – Kaizen | √ | √ | |

| Monitoring using metrics | √ | √ | √ |

| Using the DMAIC Principle in Project Execution | √ | √ | |

| Use of statistical methods to reduce Process variability | √ | √ | |

| Identification and elimination of losses and unproductive costs in progress | √ | √ | |

| Increasing the speed of the process | √ | √ | |

| The “pulling” principle of the process | √ | √ | |

| Reducing the costs caused by “diversity” | √ | √ | |

| Elimination of losses resulting from “false savings” | √ | √ |

From this table you can see that in the Lean Six Sigma concept. The answers to the question “how to organize activities?” are taking from the concept of “Six Sigma”, and on the question “what to do?” is mainly from the concept of “Lean Management”.

At This Lean Six Sigma concept uses a combined set of measurable indicators (metrics) and a unified set of implementation methods and tools Improve. An example of a set of methods and tools used in concept Lean Six Sigma, given in table. 2.

DMAIC

| D—Define | M – measure | A – analyze | I – improve | C – manage |

| QFD “Voice of the Consumer” Kano Analysis Process mapping Financial analysis Prioritizing | Control charts Pareto charts Histogram Evaluation of the effectiveness of the process cycle Plan Data Collection | Pareto charts Ishikawa diagrams (“fishbone”) FMEA Identification of overhead costs Identification of “time traps” Constraint Assessment | FMEA Kaizen Poke-yoka Justification of batch size 5S Hypothetical testing Decision Choice | Control charts Poke-yoka Visual control of the process Plan Training The Plan Inform Plan Standardization |

The practice of using the Lean Six Sigma concept in Western enterprises allow on their own in a short time (about a year) achieve the following results:

- reduction the cost of products and services by 30-60%.

- reduction of service delivery time by up to 50%.

- reduction in the number of defective products by about 2 times.

- promotion without additional costs of the volume of work performed up to 20%.

- reduction the cost of design work by 30-40%.

- Up to 70% reduction in project lead time.

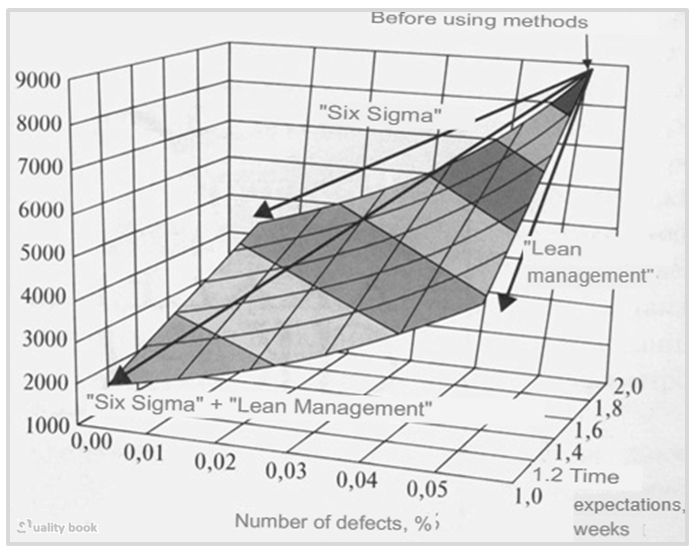

Graphical comparison of the results of the company’s activities with using the integrated concept of “Six Sigma” + “Lean Management” with the results of the concepts of “Six Sigma” and “Lean Management” applied individually, shown in the figure. The cost of each of the projects is approximately the same.

Lean Six Sigma results.

In what cases can we count on such results?

Eat Two main signs indicating the presence of avoidable losses in Processes.

- The first sign is any changes taking place in the enterprise. for example, increasing or decreasing production volumes, expanding assortment, organizational changes, innovations, etc.

- The second sign is insufficient documentation of processes and misunderstanding of the essence of processes employees involved in the process.

If these results are possible at prosperous European enterprises, then a reasonable question arises: will Does this “contraption” work with us? Before answering this question, here is an example when one of the seven simple quality tools did not “work” is the data stratification. After a seminar in one of the consulting firms, the specialist the company decided to analyze the accumulated data on defects.

Defects on this enterprise was detect by various methods:

By the method of acoustic emission, ultrasonic testing, eddy current method, magnetic particle, etc. The classifications of types of defects that could be attributes to causes the occurrence of defects did not exist at the enterprise. The array of data was stratify according to the methods of detecting defects. And then the analysis of the data for the entire period. Such an analysis did not give results, to conduct another analysis of nature data was not allow. As a result, statistical methods were forgotten, and the fight against tying the knot results in an increase in fines.

Do you need to perfectly know the entire set of tools and Lean Six Sigma metrics in order to start improvement projects?

You don’t need to.

The 80/20 principle also applies to the demand for specialist knowledge Category “Black Belt”. In the implementation of 80% of projects, less than 20% are use tools study by these specialists. The complexity of the application of the concept Lean Six Sigma lies in the simplicity of its individual elements. Most of the problems are associates with incorrect data collection and preparation, as in the example describe.

We identified several basic principles that accompany success in both application simple statistical methods.

As well as in the implementation of the Lean Six Sigma concept:

- management interest.

- excretion Resources.

- experience successful projects.

When implementing the Lean Six Sigma concept, resources include: paid staff time, the cost of training and the purchase of funds necessary for the preparation and implementation of projects.

Conclusion

The management should receive the amount of knowledge required to monitor and manage these activities. The calculation of the require for training hours, and the cost of working time for implementation projects. It can be easier to find in any textbook on the concept of “Six Sigma”. Project Leader Must have hands-on experience of participating in successful improvement projects. At all the importance of training. The experience of participating in one successful project is worth studying dozens of case studies.

Will Lean and Six Sigma take root at our facilities, or will they remain an overseas curiosity? Success breeds success. The success of the concept “Six Sigma” in the American market gave rise to. The desire to dress in the form of this concepts and other approaches. Continuing along the path of constant improvement, or, more simply, to get ahead of the competition.

In conclusion, we wish our companies success in any improvement undertakings. Such successes should awaken the desire to study and to test new concepts and methods to improve quality and reduce costs. Fortunately, the Lean Six Sigma concept allows you to improve your activities gradually, from project to project.