A maintenance schedule template is schedule management program where management define deadline to complete of maintenance for task with sequences of list tasks. The aim of this program it to reducing re-active maintenance, equipment failures and reducing percentage of breakdowns.

This may be representing routine cleaning, inspection, lubrication and tightening of machinery as well equipment.

This entire process is conducted to maintaining production resources such as equipment, machinery, devices as well other process resources. It may be actually assigned to mechanical technicians to complete on-time task.

Once the schedule tasks are completing, maintenance management can review to define the specific criteria for determine when the entire plan should be executing at floor level. This schedule can be with “consists of multiple intervals”.

Key goals of a maintenance schedule

- Practically, main purpose of the schedule maintenance should be stop equipment failures during any operations.

- This is actually part of the preventive maintenance, mean it may safe and secure the equipment.

- The objective of the maintenance can be ensuring each resources, such as equipment, machinery, devices etc. should be available as and when required.

- The maximum utilization of each equipment installed at the plant.

- Reducing breakdown time of each equipment.

- Increasing overall performance of the equipment, machinery, devices as well production.

- Keep maintain the equipment before its require the services.

- The entire maintenance management can be significantly reducing the costs of resources installed at the plant.

- Minimize loss of productivity.

The schedule maintenance gives an enough time to ensure your daily routines is safe where you are working. There is some important concern related to maintenance activities such as electrical systems, circuits, plumbing, etc., which also you can check along with it. Even you can verify the system of existing condition before it may shutdown suddenly. Overall’ the maintenance schedule is much important and essential requirements of the company.

How to create a maintenance schedule?

Pre-plan before creating a schedule

The most important part in the entire maintenance schedule is creating a basic structure for the schedule. Mostly the structure may include the list of machinery, equipment and devices, locations where resources are located, and list of the maintenance engineers available with the department. This details are much important for the entire schedule.

Creating a plan

Once you get multiple details such as engineer’s list, available resources list, and structure. Now the maintenance team should be communication with different department. Now, the following steps should be requiring:

- The planning team will be communicating with machine operators, and maintenance engineers to know which equipment are in critical condition.

- The second step is preparing the list of all the equipment, machinery and device which are in critical, later on the team will be put on priority that equipment for take at first place.

- The team will be asking to department head for availability of the time. The details of this entire will be much helpful for creating a plan.

- Now, the time is to setup the schedule as availability of the manpower, time and priority.

Training the team

The training is one of the important part of the management. It may aware the maintenance team to aware about the technical, operational and function details about equipment. Before repair or service procedure, it is much important that each technician should know well about functions of equipment. Hence, the training gives the much awareness to each team member – how to service or repair the equipment.

Review the schedule

Once the schedules are preparing for maintenance activities, it is much important to ensure that each task are set as per requirements. Well-planned schedule gives the “mistake Proof” system where you can put the aim “zero” breakdown.

Free Maintenance Schedule Example:

Actually, the machinery, equipment and other resources are much valuable asset of any business. However, it is much important to cleaning, lubrication, inspection and tightening process should be conduct over time.

The schedule is probably one of the important part of the preventive maintenance. Hence, it is helpful to keep equipment safe and secure. You can use this template to create a maintenance schedule. You can edit this template more easily, and customize suitable for your business.

Maintenance Schedule Description [Excel]

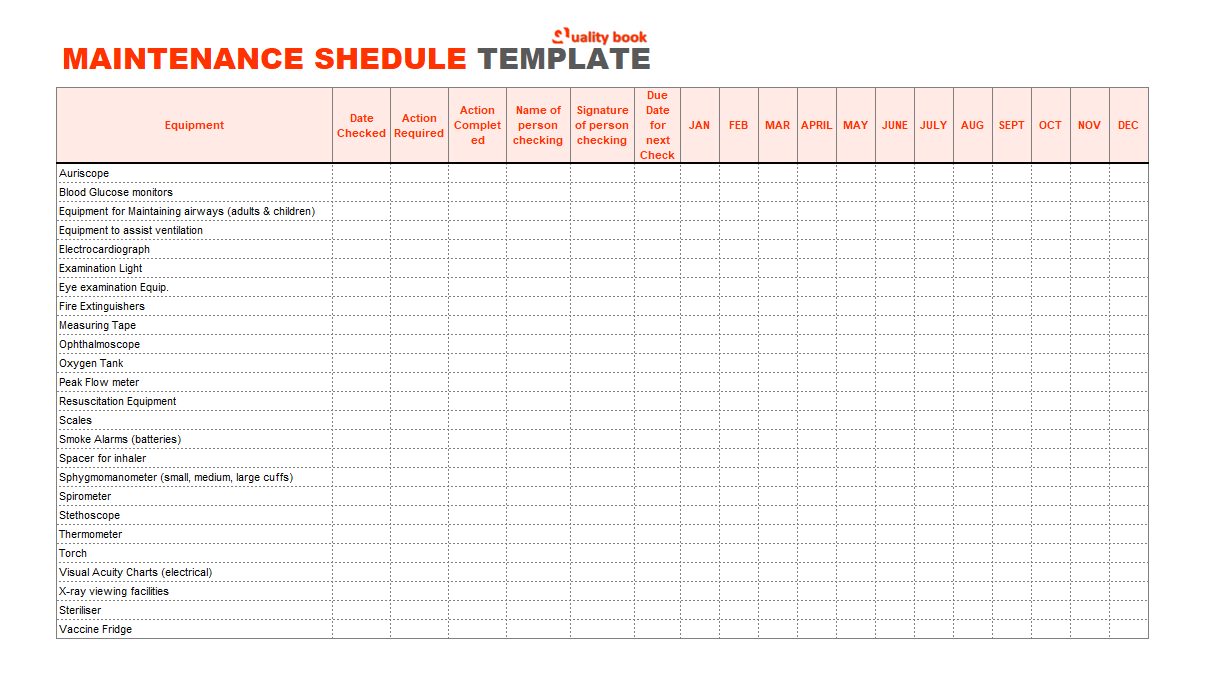

This is actually annual maintenance template that may help you to manage the schedule of each equipment installed in the facility. It may include equipment name, date of checked, action require, action completes, name of person who is checking, signature, due date of the checking, with each month checking schedule. This is actually simple but very important for the equipment maintenance.

This template also you can use for the key equipment for your workplace. All the included equipment should be needs to include in this template to follow strictly.

If you are business people, it is obvious that you well aware about time and money. To ensure the equipment and other dedicated resources are works safely in the workplace, you have to prepare schedule for maintenance over the time. There are actually many option, you can create schedule template from the scratch or download ready made template from gallery from this website. It is much important for the workplace to keep work each equipment when the production is running, even each operation are works on the schedule, hence it can be lost the productivity if any equipment failure.

The maintenance schedule is actually list of tasks that setup to complete for repairing or services of equipment with for specific time plan over the time. Typically, this schedule is executing by trained maintenance technicians. They having a special skill to conducting entire process. In this process they can conducting servicing, adjustments, inspection and replacement as and when require.