Manufacturing costs | If the manufacturing cost is reduced then there will be huge expenditure of the organization or there will be cut in provision.

Know this thing that no matter how useful you are and how popular your product is in the market. If it cannot make the organization financially profitable and effective. It will lead to loss of your business in the long run. Considering this is the right time to make your manufacturing efforts profitable. You will know that some important changes and steps have to be taken, which will directly affect the manufacturing costs.

How can you reduce manufacturing costs?

Manufacturing is the heart of any organization. Obviously most of the expenditure is provisioned (budgeted) on it. So, if the manufacturing cost is reduced then there will be huge expenditure of the organization or there will be cut in provision. You know that even the smallest increase or decrease in expenditure can have an impact on the profits of the organization. The good thing is that there is no need to take huge steps in the organization or in the manufacturing process to reduce the cost. You can reduce the cost by making some of the following simple and common changes:

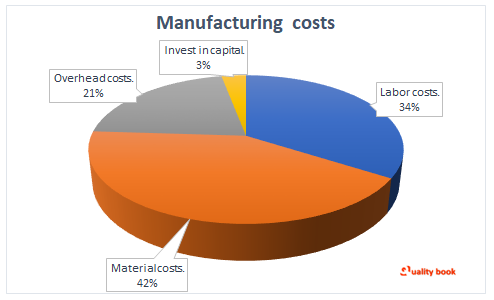

- Reduce labor costs.

- Reduce material costs.

- Reduce overhead costs.

- Invest in capital.

Before making any changes in manufacturing processes, please take a careful look at all your processes to see where. What force or energy is consumed and is this consumption really acceptable? Is this efficient energy consumption or expenditure?. Make a form of information related to all those energy consumption and expenditure. And only then decide which process and what needs to be changed. Here is list of all the manufacturing process changes that are require as below:

[1] Reduce labor costs.

If labor cost is a major part of the expenses in your production and manufacturing process. Then controlling it can work out the manufacturing cost by working out the loss. Labor cost reductions can arise by reducing the daily wages paid to factory workers or by making the workers more skilled. Although low-cost labor can be obtains through newly hire workers or unskillful workers. Another way is that due to the increase in the efficiency of old and experienced workers in labor work, there is no need for new workers.

Try to re-study the process in all the processes of manufacturing where there is scope for labor cost to work and eliminate the wasteful steps in them.

[2] Reduce material costs.

Continuous attention should be given to all manufacturing process as well as construction materials, when the cost of materials used in manufacturing works increases the product expenditure then it should focus on the way to purchase materials for less expenditure. Purchase the material in bulk to enable the manager to work out the cost of each unit, which works on one unit. Also eliminate some facilities which are not part of the quality and process.

[3] Reduce overhead costs.

What are the overhead costs of the manufacturing process? – Expenses that count towards manufacturing costs such as building, utility, supply, storage, handling, travel, supervisory and administrative costs that count directly into the manufacturing process. To control such expenses, they have to be reviewed from time to time and measures taken to control them.

[4] Invest in capital.

Investing in capital for every producer can be an important and broken decision. Because that expenditure economically consumes a large part of the organization’s budget. So keep in mind that while investing capital, review the process whether it is an expense or an investment in manufacturing. Will make the process faster and more dynamic and they will save total product cost and time. Before purchasing new equipment or new tools. It is essential to thoroughly research the costs versus the potential capital investment benefits. And pay attention that he should get the benefit and return of investment in proper time frame.