Six Sigma approach | These six Sigma approaches help us all at once and quite suddenly, as winter usually comes in our country. It seemed that the process of developing the concept of quality had more or less become stable. There was a normal flow of TQM into international standards ISO 9000, quality management gradually mastered the “warm places” in general management and was already ready to slowly absorb it. And all of a sudden, here you go, six sigma.

However, for specialists in this new fashion trend, perhaps, there is nothing unexpected. In essence, we are talking about the following. Suppose that you have negotiated with your supplier and in the course of them agreed that the tolerance for some, important for you, characteristics of the product will be equal to a certain value, for example, plus or minus 1 millimeter.

Then the task of your supplier, if he is committed to the ideas of Six Sigma, is very simple.

It is necessary, in fact, to “drive” the natural spread of this indicator in the process of production of this product into such stable boundaries that it fits into the agreed tolerance limits 12 (!) times. Which, as it is, is ± 6s (sigma is a Greek letter, which in mathematical statistics is often used to denote a quadratic error given by the distribution of some random variable).

Let’s go on a long drive!

Is that all? an astonished reader will ask. But after some reflection.

The reader may ask a few more questions, such as:

- Why?

- Why six sigma and not, say, 3 or 7?

- How can this be achieved?

In this paper, an attempt is made to sketch a general “panorama” of this concept and its relationship with other approaches developed within the framework of the modern movement for quality.

More ambitious goals had to be abandoned because of the colossal volume of materials on six sigma, which we currently have. Its description is the task of the future. Now, let’s move on to describing the situation as we understand it. And let’s start from afar.

History Window | Six sigma approach

In the mid-20th century, the process of division of labor reached the level of management, which made management a fashionable science, which managers of various levels are actively studying in practice and in countless business schools.

For half a century, a huge number of different trends and directions arose in this very young science, each of which promised its followers prosperity and success in business. For example, M. Hammer and J. Champi in his bestseller on reengineering (one of the last such trends), lists 14 fashion trends that arose only during the period of the 70s – 90s.

Among the most newfangled trends that have arisen in the last decades of the outgoing century, it is impossible not to pay attention to a very popular approach that works under a modest hat. Six Sigma. The just concluded 44th Congress of the European Organization for Quality once again showed the degree of popularity in the world of this approach.

Six sigma were not only devoted to a special session and a plenary report, but interest in them, one might say, was a red thread throughout the work of the congress. Unfortunately, the domestic industry and the scientific community are little familiar with this approach to improving organizations. The brief mention of it in the March 1999 issue of the journal, and the just published translation of the article by M. Harri, do not correspond to the scale and achievements of this style of management.

What the Six Sigma?

“Six Sigma is an approach to business improvement that seeks to find and eliminate the causes of errors or defects in business processes by focusing on those output parameters that turn out to be critical for the consumer …

Six Sigma is a strategic approach that works for all processes, products, and industries”. This approach was first developed by Motorola, whose registered trademark is reflected in this name. Recently, this approach has received increasing attention, which, first of all, apparently, is caused by the impressive economic achievements of those companies that declare their commitment to this direction. In particular, the above publications provide the following figures.

Example for Historical Data

Allied Signal reported an economic impact of $800 million between 1995 and 1997 through the Six Sigma Improvement Initiative. General Electric (GE) in the third quarter of 1997 reported an increase in profit from 13.8% to 14.5%, which brought it $ 600 million, “extracted through the Six Sigma Quality Initiative”. The 1999 shareholder summary indicates that the Sigma Initiative in 6 generated more than $1999 billion in profits for the company.

Here’s how General Electric defines the concept of 14 Sigma in its brief glossary: “Six Sigma is a vision of quality equal to just 15.3 defects per million opportunities for any product or service. Striving for excellence.”

What is Six Sigma from a statistical point of view?

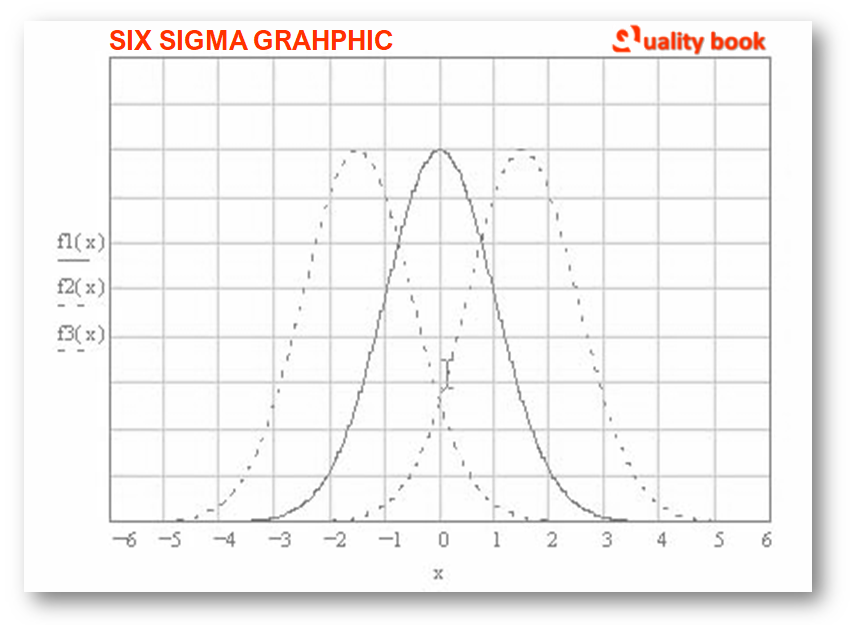

The point is that the company’s goal is to implement all processes so that for any parameters of any process. The reproducibility index Cp, is equal to 2.0 (or more). This condition is met by a central curve for which Cp is 2.0. If the upper and lower tolerance limits are at a distance of ± 6s from the center of this curve (this is exactly the definition with which we began the discussion). At the same time, it is known that the six-sigma concept is based on the fact that processes that meet this criterion produce no more than 3.4 defects per million products.

Strictly speaking, these two figures do not correspond to each other, because the Cp value of 2.0 corresponds to a defect level of 2ppB, i.e., 2 defects per billion products. This discrepancy is explained very simply: within the framework of the six-sigma concept, it is assumed that the distribution center can shift within one and a half sigma (see and Fig. 1) in one direction or another. Presents calculations showing how 6 Sigma turn into 3.4 defects per million products. The value of 1.5 sigma is taken from the following considerations.

Example

The fact is that as soon as, for example, automotive suppliers began to collect quarterly data on the reproducibility of processes. It turning out that the adjustment of processes “walks” within very noticeable limits.

Knowing this, Motorola from the very beginning set as its goal to achieve such a level of variability of processes that even with an uncontrolled shift in the center of tuning.

The value of the Cpk index was no worse than 1.5.

General Electric formulated the main idea of this approach as follows: “Our consumers are sensitive to dispersion, not to the average.”

A characteristic feature of the 6 Sigma concept was its close connection with the financial results of the company’s work. Within the framework of this concept, the following classification of organizations according to the criterion of reproducibility is adopted:

Table 1 Resource requirements by component

The impact of process reproducibility on the competitiveness of organizations

| Distance between distribution center and tolerance limit | Number of defects per million | Low quality cost, % of sales | Level of competitiveness |

| 6 Sigma | 3,4 | >10 | World Class |

| 5 Sigma | 233 | 10-15 | |

| 4 Sigma | 6210 | 15-20 | Industry average |

| 3 Sigma | 66807 | 20-30 | |

| 2 Sigma | 308537 | 30-40 | Uncompetitive |

| 1 sigma | 690000 |

The numbers in this table should not be treated too strictly. The fact is that the definitions on the basis of which these figures are obtains belong to operational definitions, as E. Deming like to put it, and not to strict statistical definitions. From a statistical point of view, we are talking here about the behavior of the “tails” of random variable distributions (see, for example, the work).

What is the six-sigma concept based on?

The foundations of the concept were laid, as already noted, in the company Motorola. Motorola’s approach was built according to the classical scheme of continuous improvement based on the constant application of the Shewhart-Deming cycle: plan – do – check – implement. That’s how Motorola understood the stages of this cycle.

- The first stage of “Plan”– included the formulation of goals and objectives, the identification of key parameters for success, an improvement plan, the selection of a project and the creation of a team.

- The second stage of “Do” – included education and training, plus implementation.

- The third stage “Check”– included the measurement of improvements, evaluation of effectiveness and analysis and revision of projects.

- The fourth stage “Implement”– involved adjustment of implementation, continuity of improvement, standardization, consumer research, benchmarking, redesign.

Subsequently, within the framework of the 6-sigma concept.

The Shewhart-Deming cycle was transformed into the MAIC cycle:

Measure – Analyze – Improve. Recently, there has been a tendency to supplement this cycle with a number of additional stages.

The most common variant is DMAIC – at the beginning of the cycle, the Define stage is added. Leaders of the 6th Sigma Academy Harri and Schroeder believe that this program consists of eight stages: Recognize (DMAIC) (as described above) – Standardize (Standardize) – Integrate (Integrate).

Reducing Process Variability systematically

It is worth emphasizing that in the Six Sigma Approach emphasis is not so much on the number of defects per million possibilities as on a methodology for systematically reducing process variability. Following, we draw the readers’ attention to two significant circumstances.

The urgent need to move away from the traditional 3 Sigma approach is easy to see if you imagine the output of a process consisting, for example, of 20 consecutive stages, each of which provides a given percentage of output.

If this percentage corresponds to the approach based on 3 Sigma. Then the output is:

(0.9973) 20 = 0.947, i.e., about 5% of marriage.

Whereas with;

6 Sigma we have (0.9999966) 20 = 0.99993, i.e., marriage is only 70 ppm.

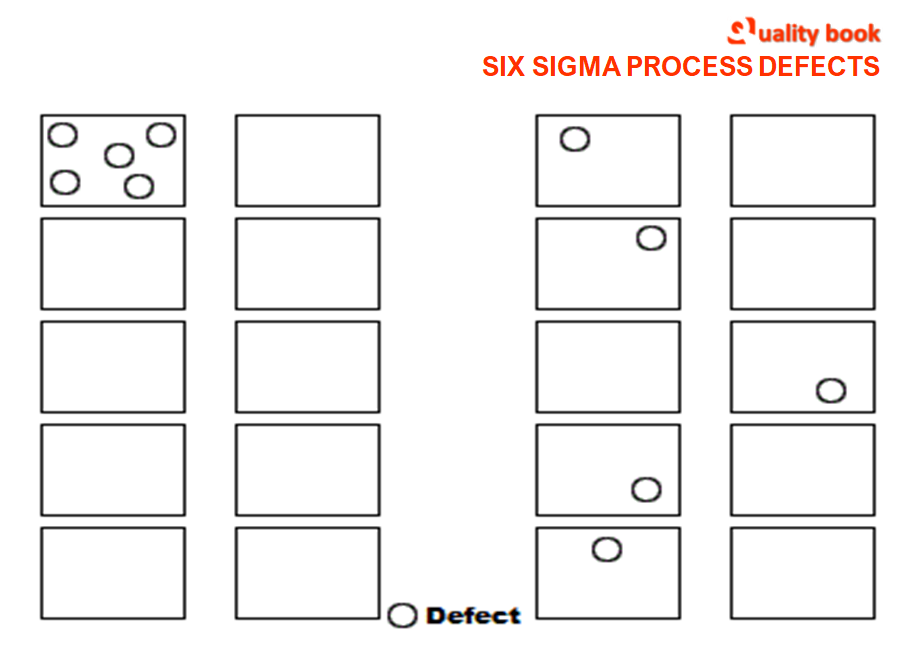

The second point has to do with the formulation of the defect level as the number of defects per million possibilities. Word the “possibilities” here are far from accidental. To explain the essence. Let’s turn to Fig. 2.

Defects

It shows two processes, one of which has a yield of 90% for products, and the other, respectively, 50% (in the first process, a defect in one product out of ten, in the second in five).

At the same time, if we assume that each product has 10 characteristics critical to quality, then in relation to the possibility of defects, both processes are the same and have an output of 95% (five defects per 100 possibilities).

If we assume that the cost of detecting a defect is approximately the same in all cases, then both processes will require approximately the same cost of eliminating defects – this is why within the framework of the concept Six Sigma is talking about opportunities, not products.

In accordance with this, such concepts as the following are specially introduced:

- Final Yield (unit-based) – the number of products that have passed the last step of a sequential set of process steps, compared to the number of products from which the process as a whole began.

- Throughput Yield (defect-based) – probability that for everyone the possibility of defects occurring at this particular stage of the process will be implemented compliance with the standards.

- Rolled Throughput Yield (defect-based) – the probability that a single product or service will pass through the entire process free of defects.

It is important to note that among the key conditions for success in this action program, from the very beginning. Such important aspects of modern management as leadership, including top-down initiative, commitment to this approach and active participation in it.

Clarity and coherence of goals, “breakthrough” thinking, project lifestyle, teamwork, training, support for successful actions and achievements.

Approach Span

In other words, for all its statistical orientation, this approach was very broad from the very beginning, and aimed at creating a certain social and cultural environment in the organization. Such an expansion of the concept far beyond the purely statistical approach, in our opinion, is due to the fact that Motorola was one of those advanced firms that first realized the advantages of statistical thinking associated with the names of W. Shewhart and E. Deming and managed to develop a system concept for its implementation.

The fate of statistical thinking in the 20th century was not too happy. For almost 50 years, Shewhart’s ideas were sometimes misunderstood, then distorted. His favorite brainchild – control charts – became widespread, but mostly not for the purposes for which they were proposed.

And only in the 80-90s began a revival of interest in this approach. It turned out that it organically fits into the new style of management, without which it is impossible to achieve any sustainable development in modern conditions.

Motorola Six Sigma

It must be said that Motorola six sigma itself also did not save from the severe crisis that broke out in the mid-90s. Nothing foreshadowed trouble. From 1993 to 1995, the company’s annual sales growth rate was about 27%. But already in 1997, they were only 5%.

During the same time, the company’s profit decreased by as much as 33%. Such indicators did not take long to affect the dividends. From 1995 to 1997, they did not exceed 1% of the value of the share, whereas in the previous three years they reached 54%. Such a course of events always leads to the loss of the best customers.

Meanwhile, back in 1988, the company received the Malcolm Baldridge National Quality Award (this was the result of a ten-year quality improvement program) and since then has continuously confirmed its reputation as a company committed to quality. Excellent achievements in the past can be caressing the ear, but they mean little in the present, and, especially, in the future. And in 1998, Motorola was inundated with complaints and claims from consumers who were not satisfied with the quality of products.

Mis Management Decisions

Today we know that the company had the strength and determination to get out of this deep crisis. And this happened, too, at least in part, thanks to Six Sigma, plus, of course, thanks to a number of new approaches to organizing the work of people in teams. 1997 began with the coming to power in the company of Christopher Gelvin, the grandson of the founder.

Here’s what the diagnosis of the initial situation was by this point, following the work: “… the reason for the fall was arrogance and complacency.

The company’s management refused to recognize the merits of more advanced technologies, did not notice, or refused to notice new trends in sales markets and did not pay attention to the requests of buyers. All this was followed by incorrect management decisions, a poorly calculated strategy and a far from perfect practice of implementing plans. ”

Recovery

And here is the first recipe for recovery, quoted from the same source: “Gelvin began the struggle to create a new corporate culture at Motorola. In his opinion, the company developed an atmosphere of some complacency, with the main forces spent on solving purely technical problems, and inside it was corroded by an unhealthy rivalry between individual divisions.

To establish a spirit of cooperation, he decided to link the payment of remuneration to the heads of departments not with the results of their work, but with the achievements of the company as a whole. ”

It turns out that six sigma is not a panacea, but also not a completely useless thing. So let’s see what is taught within this concept. Six Sigma training.

Concept “Six Sigma”.

In the course of the introduction of this approach, non-trivial ways of motivating staff were found – awarding those who learned to apply the concept of six sigma with belts of different colors, as in karate fashionable in those years.

The so-called Six Sigma Academy appear, where specialists of various organizations are train. After which they receive the title of “Six Sigma Black Belt”. The fact is that if you look at the content of the subjects included in the six sigma, you will easily find that it almost entirely fits into the applied methods of mathematical statistics and experimental planning. And these are, as you know, “boring matters”.

So, in order to “sweeten the pill”, a game of multi-colour belts turning out to be very useful (not only black – for real masters of their craft, but also green – for people less sophisticate, and yellow – for those who just got a general idea of the approach), awards, titles, and other accessories, the role of which is often underestimated. And in vain.

In fact, within the framework of the 6 Sigma concept, a certain infrastructure is created, through which, first of all, the actual introduction of this approach into the culture of the organization takes place. The list of persons who can be called agents of 6 Sigma is as follows: champions and sponsors. Black Belt Master. black belts. green belts. yellow belts.

Here are brief explanations of the functions that each of the listed categories performs under the Sigma 6 program (emphasis in parentheses is given to the corresponding definition from the General Electric glossary).

Champions and sponsors.

A champion is usually one of the top executives who knows the 6 Sigma ideology and actively strives to implement it successfully (for example, the executive vice president of a company). In addition, champions are usually called all opinion leaders who apply the methods of 6 Sigma in their daily activities and share these ideas at any opportunity. Sponsors are process owners who assist the Sigma 6 initiative and coordinate related activities within their responsibility.

Black belt masters

Are people with the highest technical and organizational skills. They provide technical guidance for the 6 Sigma programs. Black belt masters should not only know everything that black belts know, but they should understand what certain statistical methods are based on and should also be able to correctly apply these methods in non-standard situations. Usually, black belt masters themselves teach statistical methods to black and green belts.

(First of all, these are teachers. They also check and teach black belts. The selection criteria for black belt masters are quantitative skills and the ability to teach and be a mentor. Black Belt masters are fully engaged in this work.)

Black Belts

Are individuals who have been educated and trained in a special program and devote 6 to 50% of their time working on 100 Sigma projects. In the company “Polaroid” (existing at the time of writing, Markus Hina) these people are called “leaders in reducing variability”.

Black belt training often follows the following pattern: a week of training – 3-4 weeks of applying the studied methods in the workplace during the implementation of the next Sigma 6 project. Then again, a week of training, etc.

(Team leaders responsible for measuring, analyzing, improving, and managing key processes that drive customer satisfaction and/or productivity growth. Black Belts are fully engaged in this work.)

Green Belts are the leaders of specific projects, leading their respective teams. They receive a reduced training course (6 – 10 days), and unlike black belts, they spend only a small part of their time on 6 Sigma projects.

(Similar to black belts, but not all the time busy with this work.)

Yellow belts

Are often temporary workers who have received introductory training in DMAIC tools so that they can consciously participate in the work of teams led by black and green belts.

The approximate order of numbers for some of the above groups is as follows. It is generally accepted [20] that for a company with 1000 employees it is desirable to have: – black belt master – 1 – black belts – 10 – projects 6 sigma – 50 … 70 per year (5… 7 projects for a black belt per year) At the same time, savings from one project on average range from 150 to 240 thousand US dollars.

Harry and Schroeder offer this estimate [20]: an organization needs one black belt for every $10 million in turnover. So, GE, with a turnover of $190 billion, needs roughly 19000, <> black belts.

We emphasize here that all the proposed knowledge “fits into the context” of the project lifestyle and team organization of work. Here is a list of statistical training courses at Motorola [6] shown in Table 2:

Table 2 Resource requirements by component

| Course Name | Number of hours |

| Overview of the Statistical Process Control (SPC) course | 2 |

| Identify, collect, and visualize data | 4 |

| Histogram | 4-6 |

| Pareto charts | 4-6 |

| Analysis with cause-and-effect charts | 2 4 |

| Multivariate analysis | 2-4 |

| Statistic I: For SPC tools before and after the experiment | 6-12 |

| Process reproducibility | 4-6 |

| Quantitative control charts | 4-6 |

| Analysis of measuring systems | 4-6 |

| Control cards by qualitative characteristics | 3-5 |

| Statistics II: For the planning and analysis of experiments | 16-24 |

| Comparative experiment: B with C | 5-7 |

| Factor experiment | 16 |

| Fractional factor experiment | 16 |

| Component Analysis | 4-6 |

| Design for manufacturability | 16 |

Please note that of the 112-146 hours of training, 57-69 (approximately 50%) are devoting in this program to the study of experimental planning methods. In other companies, the program may differ slightly. But on average, black belts are training on a course of about 150-160 hours.

It is worth noting that there is no standard training program yet, although work is underway towards its creation.

Why does six sigma work?

We know from the experience of many countries, including our own experience. That in the past statistical methods were very tightly introducing into real production practice.

Why, now, should the same statistical methods work?

Answering this question, Ronald Sney in the work gives such arguments.

- Firstly, because now statistical methods are combined with a process approach and taking into account the human factor.

- Secondly, because this time a systematic approach was used that integrates all aspects of the case. All this inspires hope and so far, it seems, is not refuted by practice.

In the work, in our opinion, it is very well formulated why this concept turned out to be so fruitful.

Here is this list in our free presentation:

Improvement of organizations on the basis of an integrating approach, that combines a focus on processes and, if possible, the fullest possible use of the human factor. Sin emphasizes that within the framework of Sigma, all relevant components are most fully used, which explains the achievements of this management style.

Orientation to the final financial result. No Sigma 6 project is approve unless its end result is determine in the form of profit.

Combining improvement tools into a single system. An orderly approach based on the MAIC cycle (or its equivalent) plus a strict time constraint on projects (from three to six months) plus the effective use of well-known and powerful methods with the help of well-trained teams – all this taken together has created such a high efficiency, which has already been mentioned above.

In addition, the establishment of an infrastructure to support improvement activities with the required resources is one of the most important features of the Sigma 6 approach. The author [23], for example, believes that it was the lack of such infrastructure that led to the failure of about 80% of all TQM implementation projects in the recent past.

Critique of the Six Sigma Concept

Like any other approach, Six Sigma has its ardent fans and equally ardent opponents. In particular, the May issue of Quality Digest published an article by Ramberg in defense of the concept, and next to it an article by Stamatis against it.

Summarizing the contents of this article, as well as the letters of J. S. Miller. By Seddon and T. Petersen in Deming’s network, the main objections can be summarize as follows:

the concept of six sigma leads to the fact that the main thing for black belts is not consumer satisfaction, but the question:

“What savings will this project bring?”

Six Sigma is an assessment tool that has nothing to do with preventing problems.

most black belts recognize that 90% of the improvements are achieved with 20% of what they received in the learning process.

6 sigma grams are only effective in companies with a strong policy culture (black belt masters report spending up to 60% of their time collecting data and reporting on projects). If the pressure from above eases, all improvements will stop.

Training a corporate client at a Sigma 6 academy costs between $1 million and up – this is only acceptable for huge companies.

The 6 Sigma concept does not use Deming’s system of deep knowledge and does not imply a change in the culture of the organization and its management style – so this is another fashionable passing hobby, bringing huge profits to those who trade it.

We will not discuss these points here, primarily because in this article our primary task was to give readers as broad an overview of the concept of 6 Sigma as possible, including its possible negative aspects. Here it would be necessary to discuss the problem of the relationship of this concept with other well-known approaches to improving organizations, such as TQM, Deming’s approach, lean production, quality awards, etc.

Losses and Six Sigma

It is clear that this cannot be complete within the framework of this article. So we will confine ourselves to the thought of experts, with which the authors agree:

All quality initiatives, such as ISO 9000, TQM, quality awards, etc., may or may not achieve their goal.

Which depends on how much their implementation is accompanied by an understanding of the system of deep knowledge, and the corresponding transformation of the culture of the organization.

The same, in our view, applies to the Sigma 6 initiative, which began as a simple statistical initiative to reduce losses and then grew into an organizational restructuring program. In other words, all roads lead to the temple, unless we stop there, but constantly, everywhere, and all together looking for ways and means to improve ourselves, our organizations, and our business.

Six Sigma: What Was, What Will Be and How the Heart Will Calm Down

If you ask if there was anything in the world before the concept of Six Sigma, the answer is yes. It is safe to say that Six sigma were precede by an approach call “zero defects” or “defect-free”. Maybe he was not advertise with such pomp as Six sigma, but he plays his own, and at the same time very noticeable, role.

Although it is generally accept that the idea of defect-freeness ended in failure. Its manifestations can be found in many modern approaches.

You don’t have to be a famous fortune teller to predict the fate of six sigma, of course, in general terms. There will be a “showdown” of six Sigma with all other concepts and approaches operating in the field of quality. This process has already begun.

For example, discusses the relationship between six sigma and the QS-9000 standards. It highlights the great potential of the Six Sigma approach for the automotive industry. At the same time, attention is drawn to some inconsistencies and inconsistencies that require further work.

Another obvious direction of development is the introduction to the organization of small and medium-sized businesses, and not in the giants where this movement originated, as well as in other areas of business than industry.

Example

There are examples here, too. Thus, the work discusses the introduction of six sigma in Enterprise. In this Enterprise, to reduce the service cycle time and increase customer commitment.

It is propose to use a process that includes five stages:

- Planning (2-4 weeks),

- Building a flowchart (flow chart) of business processes “as is” (2-5 days).

- Involving employees who did not participate in the work of the team (3-5 weeks).

- Building a model of the desired state “as we would like” (3-5 days) and

- Detailed development and implementation (5-10 months).

The interaction of six sigma with the concept of prudent (gentle) production is discuss in the work, it is clear that all comparisons of this kind are just beginning, although for quite some time the American magazine “Quality Progress” has been publishing articles on six Sigma in almost every issue.

What’s next?

Judging by the way events unfold, the concept of six Sigma is waiting for a turbulent and, apparently, quite long, life, and then something new will appear, and the Sigma will begin to fade into the shadows, they will be forgotten. It’s natural: “everything passes.”

But that’s not what matters. What matters is what will remain next. Because as long as there is a consumer market, there remains a seller whose task is to unconditionally satisfy any desires of the consumer in the most effective way. And in this regard, statistical methods, whatever forms they take, will serve the seller faithfully and truthfully. Therefore, six Sigma have a chance, changing and adapting, to remain in eternity.

Conclusion

In general, the history of development and the results of the introduction of this approach demonstrate, as it seems to us, a very simple idea: from whatever side you start work to improve the organization, and no matter how you call your approach (six sigma, TQM, quality award, etc.), still, the road leads to the same peak (temple): the prosperity of organizations and their employees based on the concept of win-win – “winning together”. For you can only win together.